- The injection unit is available as a fully hydraulic version (UAI) or hybrid (UAI Hy) version

- 3 different sizes which cover a range of volume from 1 to 60cm³ –

- Rear lit touch screen display LCD 8″

- 10 different languages

- Easy to consult, user-friendly display

- Safety key for starting a cycle via the screen.

- Removable display

- Quality control on 5 cycle parameters.

- PID temperature control (max 420°C)

- 4 zone PID temperature control of which one is for auxiliaries (hot runner)

- Sprue break

- I/O interface Euromap 62 or 67

- Handles and stores over 1000 tool settings

- USB connection for backup of tool settings

- Electronic transducer for pressure control

- Injection and clamp positions monitored via transducers or encoder for the hybrid versions

- Proportional hydraulics

- Inverter for motor speed control

- Outputs for Shut off nozzles

- Expansion board for the control of shut off nozzles (optional)

- Low running costs – rated power 3 to 8 Kw – cooling approx. 120 l/h

- 3 injection units:

- I/12 – I12Hy 5 piston sizes from 3 to 15 cm³ with pressures from 2050 to 815 bar

- I/25 – I/25Hy 5 piston sizes from 16 to 36 cm³ with pressures from 1535 to 680 bar

- I/60Hy 5 piston sizes from 25 to 60cm³ with pressures from 1240 to 550 bar

- Cooling circuit

- Temperature tolerance band

- Core pull and air blow (optional)

- Integrated control and storage of power consumption (optional)

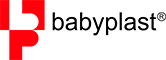

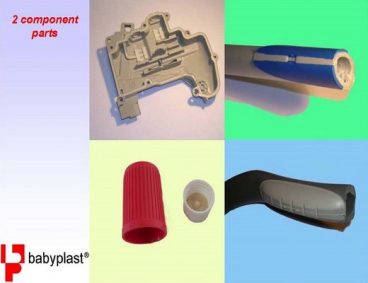

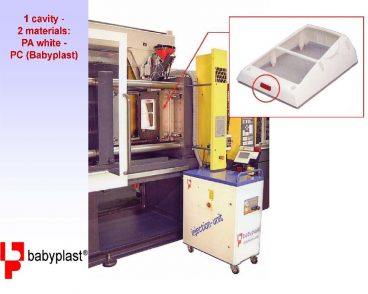

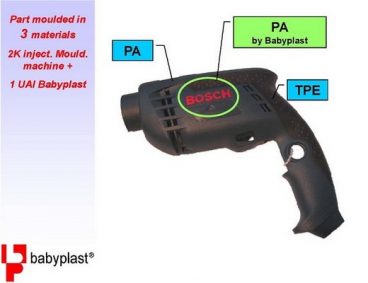

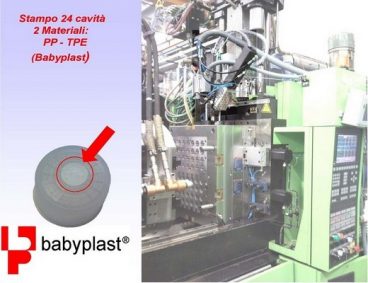

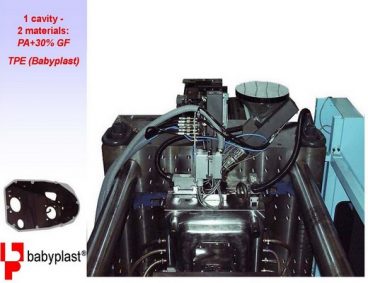

A small unit for big machines

The original concept of this Autonomous Injection Unit has been developed, based on the experience accumulated from thousands of applications using the Babyplast injection moulding machine. After hundreds of installations on a vast range of various injection moulding machines, we can confirm that the Babyplast UAI is the best alternative solution for multi component injection moulding.

Typical applications include:

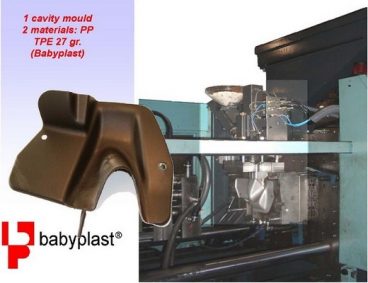

- Transformation of standard injection moulding machines to multi component machines.

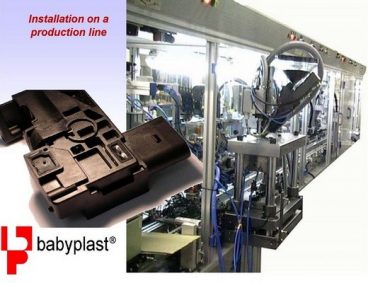

- Installation, of the injection unit, directly on machines/automatic assembly lines.

The Babyplast Autonomous Injection Unit is comprised of an injection unit, which can be installed directly onto a mould, plus a control unit on wheels, which contains the electronics and the proportional hydraulics. The connection to the injection moulding machine can be carried out quickly and easily, thanks to a Euromap 62 or 67 interface. Any injection moulding thermoplastic material can be processed with processing temperatures up to 420°C.

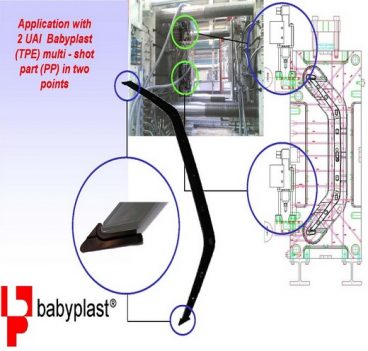

Due to the compact design of the injection unit, it can be installed directly on the mould (via suitable fixing plates), on either the fixed or moving half, horizontally or vertically. This means it is possible to choose the best injection point, for the second component, without being governed by the design or construction of the main moulding machine.

The advantage of the injection unit, for multi-component moulding, is that it is completely autonomous regarding the electronics and hydraulics. Also, the UAI can be connected to any injection moulding machine or integrated directly into an automatic assembly line, thanks to a simple interface.

Since with most multi-component applications, the main component is usually of a much greater volume than that of the second component, the lower shot volumes for the UAI (from 3 to 15 cm³ for the I/12 and I/12 Hy injection units, from 16 to 36cm³ for the versions I/25 and I/25 Hy to a maximum of 60cm³ for the version I/60Hy) allow the possibility to obtain precise injection shots and minimum resident times at melting temperature. Hence, the Babyplast UAI, offers both an economical and practical solution for transformation of an existing, traditional, single component injection moulding machine, into a multi-component machine.

Injection unit (Hydraulic)

| Unit | UAI I/12 | UAI I/25 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Piston diameter | mm | 10 | 12 | 14 | 16 | 18 | 16 | 18 | 20 | 22 | 24 |

| Volume | cm³ | 4,7 | 6,8 | 9,2 | 12 | 15 | 16 | 20 | 25 | 30 | 36 |

| Injection pressure | bar | 2.025 | 1.830 | 1.340 | 1.030 | 815 | 1.535 | 1.210 | 980 | 812 | 680 |

| Injection speed | mm/sec | 55 | 50 | ||||||||

| Power consumption | kW | 3 | 3,5 | ||||||||

| Injection unit weight | Kg | 25 | 35 | ||||||||

| Total weight | Kg | 145 | 155 | ||||||||

| Hydraulic pressure | bar | 130 | |||||||||

| Oil tank capacity | l | 15 | |||||||||

| Power supply | 3F - 230/400V - 50/60 Hz | ||||||||||

| Injection unit dimensions vertical A-B-C-D | mm | 535 - 65 - 345 - 14 | 570 - 70 - 415 - 34 | ||||||||

| Injection unit dimensions horizontal A-B-C-D | mm | 525 - 65 - 395 - 14 | 570 - 70 - 440 - 34 | ||||||||

| Dimensions of control unit on wheels | cm | 790 x 500 x 1030h | |||||||||

Hybrid injection unit (electric injection)

| Unit | UAI I/12 Hy | UAI I/25 Hy | UAI I/60 Hy | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Piston diameter | mm | 10 | 12 | 14 | 16 | 18 | 16 | 18 | 20 | 22 | 24 | 16 | 18 | 20 | 22 | 24 |

| Volume | cm³ | 4,7 | 6,8 | 9,2 | 12 | 15 | 16 | 20 | 25 | 30 | 36 | 27 | 34 | 42 | 51 | 61 |

| Injection pressure | bar | 2.050 | 1.950 | 1.430 | 1.095 | 865 | 1.240 | 980 | 795 | 660 | 550 | 1.240 | 980 | 795 | 660 | 550 |

| Injection speed | mm/sec | 250 | 125 | 125 | ||||||||||||

| Power consumption | kW | 7 | 7,5 | 8 | ||||||||||||

| Injection unit weight | Kg | 50 | 60 | 70 | ||||||||||||

| Total weight | Kg | 170 | 180 | 190 | ||||||||||||

| Hydraulic pressure | bar | 130 | ||||||||||||||

| Oil tank capacity | l | 15 | ||||||||||||||

| Power supply | 3F - 400V - 50/60 Hz | |||||||||||||||

| Injection unit dimensions vertical A-B-C-D | mm | 685 - 86 - 342 - 15 | 756 - 86 - 412 - 35 | 915 - 86 - 475 - 15 | ||||||||||||

| Injection unit dimensions horizontal A-B-C-D | mm | 685 - 86 - 395 - 15 | 756 - 86 - 440 - 35 | 915 - 86 - 527 - 15 | ||||||||||||

| Dimensions of control unit on wheels | cm | 790 x 500 x 1030h | ||||||||||||||

The Autonomous Injection Unit

Allows the injection of multi-colour or multi-materials on a standard injection moulding machine.

UAI Hy - “Hybrid” version (electric injection)

The injection process, on the “Hybrid version” (UAI Hy), is actioned by a brushless motor, which is controlled via an inverter. The position, on the other hand, is controlled by an encoder in order to obtain the highest precision during the injection process. All other movements are hydraulic and are controlled by an inverter, via a high-performance motor pump assembly. The motor pump assembly, is situated in an oil tank which is easily accessible.

UAI - Fully hydraulic version.

All movements are hydraulic and are controlled by an inverter, via a high-performance motor pump assembly. The motor pump assembly, is situated in an oil tank which is easily accessible

Installation directly on the mould

The UAI can be installed directly onto the mould, either horizontally or vertically, and either on the fixed half or on the moving half via

Movements

The machine movements (pressures and speeds), temperatures and times, during the production cycle, are governed and controlled by powerful CPUs.

Maximum safety

Interface with I/O alarm signals and safety guards controlled by a safety module. TUV certification.

Colour touch screen display

USB ports and connections for ethernet or WIFI with protocol Modbus TCP or OPC-UA

Cooling circuit

The flow of the cooling fluid, in the injection unit, is controlled via a manually regulated water manifold. In the other parts of the machine, the flow of the cooling fluid is controlled automatically by the electronics of the machine.

Hot runner control

An extra heater zone is available, as standard, for controlling a hot runner.

Control of hot runner with shut off nozzles.

The unit has an output for the control of a single shut off nozzle in the mould. It is also possible to control sequence shut off nozzles (optional).

Venturi loader

RB081AV - Designed specifically for Babyplast; it helps the supply of materials which are normally difficult to load.

- Complete with venturi;

- Reduced weight: about 600g instead of 6 kg, which is the weight of a standard loader;

- It can also be installed on the standard hopper;

- Use in a clean room: the air used can be directed out of the clean room;

- Direct control via the display of the Babyplast/AIU;

- Possible to contain and maintain a few grammes in the hopper.

ATTENTION: USE ONLY DRY AIR

Nozzles

A wide range of nozzles is available for various requirements:

- RB006UO - Shut off nozzle;

- C1006656400 - Mixer nozzle - to obtain uniform colour using masterbatch. Available with a standard injection hole or with a 1 mm diam;

- C20004100 - Nozzle with a hole diam. of 1mm;

- RB008PEW - Nozzle for direct injection - direct injection into the part is possible low temperature materials (max 240°C) without using a hotrunner.

Material loader

RB003VH - For the Supply of plastic granules - 230V-1-50/60Hz.

Dehumidifier

RB051DE - Dehumidifier F. Micro2000

- Cap. 1.5 dm³;

- 1/230V/50Hz -250W;

- Max temp. 180°C with venturi supply and loading sensor - Babyplast adapter.

Minimal energy consumption, it allows the material to be kept dehumidified and at the pre-heating temperature. Installed directly on the Babyplast plastification unit

ATTENTION: USE ONLY DRY COMPRESSED AIR

Chiller

RB003AT - Chiller

- Cooling capacity 3.9 Kw;

- Rated power: 1.5 Kw;

- 575à445 h.640;

- Weight 77 kg;

- 230V/1/50/60Hz.

Pneumatic Shutter Nozzle

Augmented Plastification Unit

Augmented Plastification Unit increases the volume of the plastification chamber from 15cc (standard) to 30cc

Augmented Injection Unit

Augmented Injection Unit increases the injectable volume, available with pistons having a diam. of 16mm( 16cc) – 18mm(20cc) -20mm (25cc) – 22mm(30cc) – 24mm(36cc).