- Backlit 8″ touch screen LCD

- Cooled machine nozzle with pneumatic pin shutter for direct injection on the piece

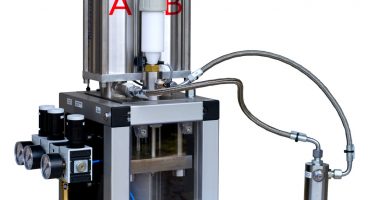

- 3 different configurations: premixed 0.5 kg cartridge – mixer with a dispenser (1 kg cartridges A+B) – mixer with a dispenser (20 kg containers A+B)

- 10 different languages can be selected

- Easily accessible pages thanks to multi-function buttons

- Security key to enable the start-up cycle from the keyboard

- Removable keyboard

- Quality Control on 4 cycle parameters

- PID temperature control

- Injection carriage movement

- I/O interface with voltage free contacts

- Manages and stores over 1000 production cycles

- Program back-up USB output

- Ethernet Connection : TCP modbus

- Pressure control with electronic transducer

- Injection position control with linear transducer

- Proportional hydraulics

- Very quiet motor pump controlled by an inverter

- Control output for shutter nozzles

- Low running costs – installed power 3 kW – cooling approximately 120 l/h

- 5 pistons of 3 to 15 cc with 2650 to 815 bar

- Output for auxiliary control

- Cooling circuit

- Air blow and jack control

Small module for large machines

The original design of this Autonomous Injection Unit is based on the experience matured in thousands of applications on the Babyplast machine. After several hundred installations on many types of machines, it can be said that the Autonomous Injection Unit UAI 6/10P is a winning alternative in multi-material moulding.

| Unit | UAI I/12 LSR | |||||

|---|---|---|---|---|---|---|

| Piston Diameter | mm | 10 | 12 | 14 | 16 | 18 |

| Volume | cm³ | 4,7 | 6,8 | 9,2 | 12 | 15 |

| Injection Pressure | bar | 2.025 | 1.830 | 1.340 | 1.030 | 815 |

| Power Consumption | kW | 3 | ||||

| Injection Unit Weight | Kg | 25 | ||||

| Hydraulic Pressure | bar | 130 | ||||

| Oil Tank Capacity | l | 15 | ||||

| Dry Cycle | sec. | 2,4 | ||||

| Noise Level | db | <70 | ||||

| Power Supply | 3 ~ 400V. 50/60 Hz. + Neutral + Earth 3 ~ 230V. 50/60 Hz. + Earth 1 ~ 230V. 50/60 Hz. + Earth |

|||||

Fully hydraulic movements.

All the movements of the machine are controlled by a high performance motor-pump assembly situated in an easy to access oil tank.

Special machine platens.

The original concept of the platens and tie bars, means only the cavity plate has to be made, thus reducing the construction and cost of the moulds.

Movements

The machine is controlled by two micro-pocessors, which control all movements, times and temperatures durng each production cycle.

Proportional hydraulics

Thanks to the proportional hydralics, the hydraulic pressures are controlled and saved by the machine.

Maximum safety.

CE certificate.

Mould safety.

Clamp closes in low pressure.

Display - LCD.

Cooling circuit.

The flow of cooling fluid, to the various zones, including the mould, is controlled by a 4 zone manifold.

Mould heating or hotrunner.

The machine has a spare 230 Volt heater zone for the mould or hotrunner. for the mould heating it is possible to insert cartridge heaters in the mould and control them in % or in °C (using a thermocouple), or else it is possible to use a 230V nozzle or hotrunner with temperature controlled by the machine.

Off centre injection.

The injection unit has two injection positions. One in the centre and one 25mm off centre. For a single cavity, when it is not possible to inject in the centre (esthetic reasons), it is possible to position the cavity in the centre of the mould and inject from the side.

Pre-mix cartridge

Configuration with 0.5 kg cartridge operation with pre-mixed material. It does not require a dispenser to be used and a mixer to be installed on the machine. A unique Babyplast solution that allows those who already own a dispensing mixer with which to load the cartridges to be used on Babyplast LSR to produce small batches or samples at low costs.

1kg two-component dispenser

Configuration with mixer and pneumatic two-component dispenser (A and B) with 1 kg cartridges. Allows the use of Babyplast LSR with an autonomy of about 7-8 hours of operation. Optional colouring cartridge.

20 kg two-component dispenser

Configuration with mixer and pneumatic two-component dispenser (A and B) with 20 kg containers. Allows the use of Babyplast LSR with an autonomy of a few days of operation. Optional colouring cartridge.

Electronic

Material: POM

N° cavities: 4

Part Weight: 0,02 gr

Shot Weight: 1 gr