- Backlit 8″ colour touch screen LCD

- Vacuum function for the mould

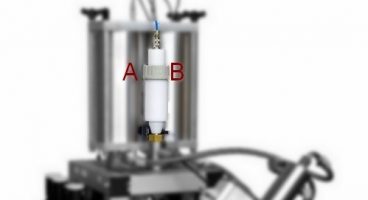

- Cooled machine nozzle with pneumatic shut off valve for direct injection into the part.

- 3 different configurations: premixed 0.5 kg cartridge (A +B components) – loader mixer (1 kg cartridges A+B) – loader mixer (20 kg containers A+B)

- Various different languages can be selected

- Easily accessible pages thanks to multi-function keys

- Quality Control on 4 cycle parameters

- PID temperature control

- 4 temperature control zones with differentiated mould temperature adjustment (moving and fixed half)

- Manages and stores over 1000 production cycles

- Program back-up USB output

- Ethernet Connection : TCP modbus

- Pressure control with electronic transducer

- Injection and clamp position controlled with linear transducers

- Proportional hydraulics

- Very quiet motor pump controlled by an inverter

- Euromap 67 card (optional)

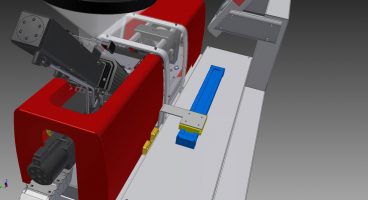

- Savings in the construction of the mould thanks to the machine platens which act as bolsters. Hence only the cavity plates need to be made.

- Low running costs – installed power 3 kW – cooling approximately 120 l/h

- Off centre injection technology – 5 pistons of 3 to 15 cc with 2650 to 815 bar

- Output for auxiliary control

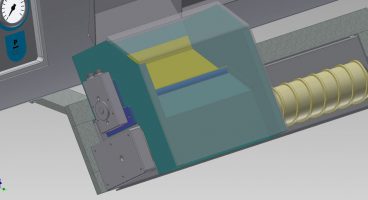

- Cooling circuit (6 zones)

- Temperature tolerance band

- Hydraulic ejector with ejecor return control sensor

- Air blow and core pull control

Quality of parts produced

- Mould with few cavities. Simple dimensional accuracy. Thanks to the low hourly cost you can obtain a competitive cost even with moulds with a few cavities.

- Easier to balance cavity layout.

- Homogeneous mould temperature. Thanks to the compact size of the mould and the positioning of the thermocouples (fixed and moving half) near the cavities.

- Temperature control of the injection unit. Thanks to its compact size, the material in the injection unit after being mixed is a few cubic centimetres, and the injection unit, including the nozzle, is cooled. This guarantees the integrity of the material even for very small shot sizes.

Low cost of production

- Low ELECTRICAL consumption. Only 3 kW of power installed, Inverter for motor speed control. Consumption when in cycle 1.5 to 2.5 kW

- Reduced time for mould and material changing. cavity plates fixed with two screws to centre the mould on two precise sides on the machine platens. Material and colour change with approx. 150 gr.

- Low power consumption to heat the mould. The reduced mould dimensions (only the cavity plate needs to be made), reduces time and energy to achieve and maintain the correct mould temperature. Using two cartridge heaters and a thermocouple for each half mould. Mould temperature control directly from the machine.

- Low part/sprue ratio. For single cavity moulds it is possible to inject directly into the piece thanks to the shut off nozzle (standard). For multiple cavities, thanks to direct injection in the cavity plte, there is a considerable reduction of the sprue. Average weight of a sprue for 4 cavities: 0.5 gr.

- Production space in less than 1 m². Thanks to the compact size (1×0.6 m), the complete production space occupied (machine – chiller – loader mixer with 1l cartridges) can fit in less than 1 m².

- Flexibility in high production. Production is split onto multiple machines, in case of problems, only part of the production is stopped. Batches in different colour can be produced simultaneously. Starting from small production you can increase it by replicating machine/mould.

- Modularity in the mixing systems. There are 3 different systems for mixing and loading LSR: 0.5 kg pre-mixed cartridge, loader mixer with two-component mixer for 1 kg cartridges (1+1), loader mixer with two-component mixer for 20 kg containers. In this way, customer requirements can be met by minimising the investments, which range from prototyping to mass production.

Low investment in the mould

- Moulds with a few cavities. Thanks to the low hourly cost of the machine (approx. 2 to 2,5 €/h) you can obtain low production costs even with moulds with a few cavities. Especially for technical parts where the cavity cost is high, (use of slides, etc.) savings in the reduced number of cavities leads to significant cost reductions.

- Construction of cavity plate only. Thanks to the particular concept of the machine platens that act as bolsters, only the cavity plate needs to be made for the Babyplast machine.

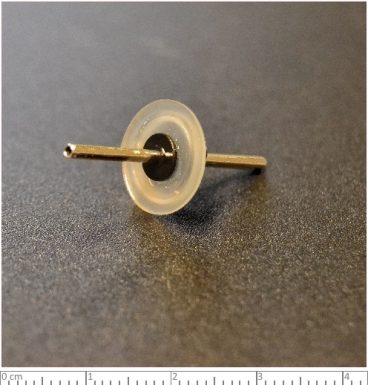

- Direct injection machine nozzle. Thanks to a special cooled machine nozzle and with a needle pneumatic shutter, direct injection is possible from the machine to the piece.

- Standard mould parts. A range of standard mould parts is also available (produced by Rambaldi or Hasco) for Babyplast moulds in different types of steel, whereby only cavity construction work is required. This allows for considerable savings in time and costs of mould construction.

| Unit | 6/12 | |||||

|---|---|---|---|---|---|---|

| Piston Diameter | mm | 10 | 12 | 14 | 16 | 18 |

| Volume | cm³ | 4,7 | 6,8 | 9,2 | 12 | 15 |

| Injection Pressure | bar | 2.035 | 1.830 | 1.340 | 1.030 | 815 |

| Power Consumption | kW | 3 | ||||

| Clamping Force | kN | 62 | ||||

| Opening Force | kN | 4 | ||||

| Opening Stroke | mm | 110 | ||||

| Ejector Force | kN | 7,5 | ||||

| Ejector Stroke | mm | 50 | ||||

| Hydraulic Pressure | bar | 130 | ||||

| Oil Tank Capacity | l | 15 | ||||

| Dry Cycle | sec. | 2,4 | ||||

| Noise Level | db | <70 | ||||

| Weight | Kg | 200 | ||||

| Power Supply | 3 ~ 400V. 50/60 Hz. + Neutral + Earth 3 ~ 230V. 50/60 Hz. + Earth 1 ~ 230V. 50/60 Hz. + Earth |

|||||

All movements are fully hydraulic

All the movements of the machine are controlled by a high efficiency motor pump unit controlled by an inverter.

Special machine platens

The original design of the machine platens act as bolsters which means that just the cavity plates need to be made. Hence, reducing the size and cost of the moulds significantly.

Movements

The moulding process is governed by two microprocessors, which control and manage the movements, the times and the temperature of the production cycle.

Proportional Hydraulics

The pressures are controlled by the machine thanks to the proportional hydraulic system.

Maximum safety

CE Certification.

Mould safety

Camp pressure is controlled while closing in low pressure.

Colour touch screen display

USB output and Ethernet connection (Modbus TCP)

Cooling system

Cooling fluid to the various points of the mould is controlled via a water manifold.

Heating the mould

Cartridge heaters and thermocouples can be fitted to each part of the mould (fixed and mobile). In this way a homogeneous temperature can be reached in the cavity plate with a minimum amount of energy. 2 mould temperature control zones are available on the machine and can be controlled via the display. Maximum temperature allowed is 220°C. The machine platens are cooled in order to protect the machine from excess heat from the mould.

Off centre injection

Pneumatic guards

C10012000 - Pneumatic guard for mould area. Complete with double start buttons to open and close guard and start cycle.

Reject parts

C10013300 - Pneumatic operated flap to reject out of tolerance parts. Installed on separator with roller "RB026SR". Controlled by activating the quality control function on the machine: Each time there is a cycle out of tolerance, compared to the previously set reference cycle, the pneumatic flap is activated and rejects the parts produced in that particular cycle.

Bench

RB002BA - Mobile bench for Babyplast - 600à1000 h900 - set up for the chiller.

Chiller

RB003AT - Chiller

- Cooling capacity 3.9 Kw;

- Rated power: 1.5 Kw;

- 575à445 h.640;

- Weight 77 kg;

- 230V/1/50/60Hz.

Euromap 67

RB067EU - Euromap 67 interface robots or UAI.

Air Blow

RB017SA - Adjustable air blow, fitted to the moving platten complete with control valve.

Hydraulic core pull

RB004MI - Hydraulic manifold for core pull.

Electrical panel

RB018QA - Auxiliary power supply panel - CE - machine controlled; if in alarm status, it disconnects the power to the auxiliaries.

Vacuum Pump

RB036PV - Pump for vacuum with pressure switch

LSR colouring dispenser 50 ml

RB016LC - LSR colouring unit to be used with an LSR loader mixer with 1 kg cartridges

LSR colouring dispenser 1L

RB017LC - LSR colouring unit to be used with an LSR loader mixer with 20 kg containers

Heater/thermocouple kit

Kit for heating moulds , consisting of cartridge heaters and thermocouples for the individualy controlled heating of the fixed and moving mould halves.

Pre-mix cartridges

Configuration with 0.5 kg cartridge system with pre-mixed material. It does not require a loader mixer to be installed on the machine. A unique Babyplast solution that allows those, who already own a loader mixer with which to fill the small cartridges, to produce small batches or samples at low costs.

1kg two-component loader mixer

Configuration with pneumatic loader mixer with two 1 Kg cartridges for two components (A and B). Allows the use of Babyplast LSR with an autonomy of approx. 7-8 hours of production. Optional colouring system.

20 kg two-component loader…

Configuration with pneumatic loader mixer for two components (A and B) with 20 kg containers. Allows the use of Babyplast LSR with an autonomy of a few days of production. Optional colouring cartridge.

Medical

Material: LSR

N° cavities: 1

Part Weight: 4.24 gr

Shot Weight: 4.24 gr

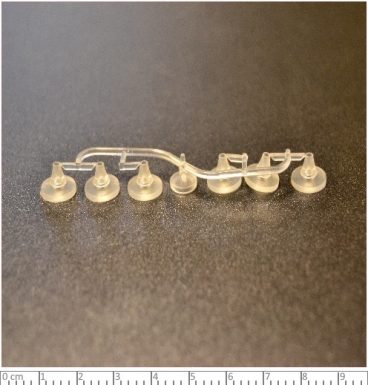

Sanitary

Material: LSR

N° cavities: 6

Part Weight: 0.17 gr

Shot Weight: 1.31 gr

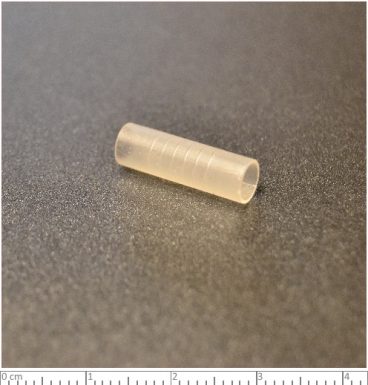

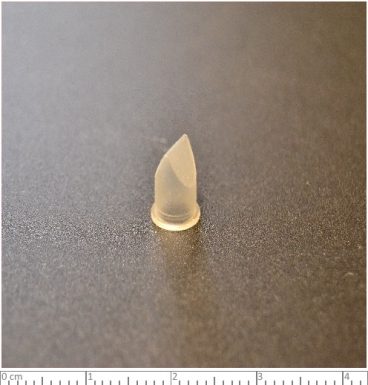

Medical

Material: LSR

N° cavities: 1

Part Weight: 0.58 gr

Shot Weight: 0.58 gr

Medical

Material: LSR

N° cavities: 1

Part Weight: 0.2 gr

Shot Weight: 0.24 gr

Medical

Material: LSR

N° cavities: 1

Part Weight: 0.27 gr

Shot Weight: 0.27 gr

Medical

Material: LSR

N° cavities: 1

Part Weight: 0.39 gr

Shot Weight: 0.39 gr

Medical

Material: LSR

N° cavities: 1

Part Weight: 0.16 gr

Shot Weight: 0.16 gr

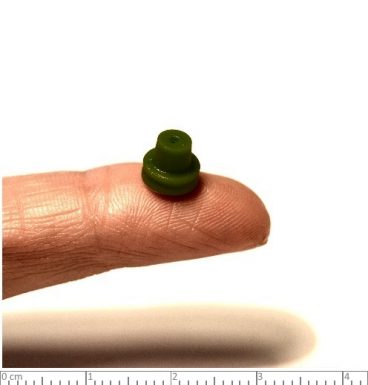

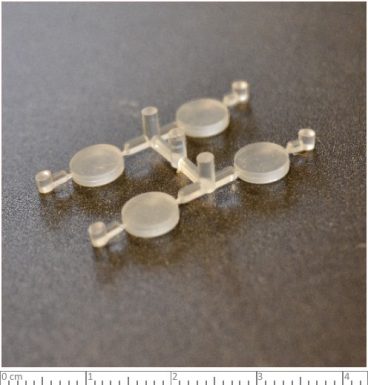

Medical

Material: LSR

N° cavities: 4

Part Weight: 0.6 gr

Shot Weight: 0.095 gr

Medical

Material: LSR

N° cavities: 1

Part Weight: 0.19 gr

Shot Weight: 0.19 gr

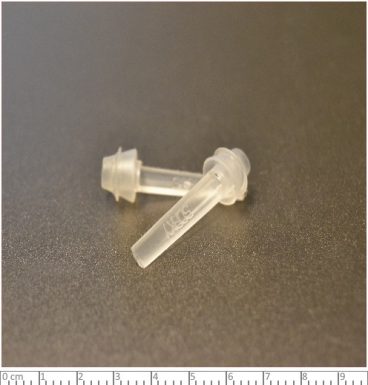

Medical

Material: LSR

N° cavities: 1

Part Weight: 0.2 gr

Shot Weight: 0.6 gr

Medical

Material: LSR

N° cavities: 1

Part Weight: 2.43 gr

Shot Weight: 2.43 gr